There are several reputable brands in the Programmable Logic Controller (PLC)

industry, each offering a range of products and solutions tailored to various industrial

automation needs. Some of the top PLC brands include:

Siemens: Siemens is one of the largest and most well-known providers of

industrial automation solutions, including PLCs. Their SIMATIC series of PLCs is

widely used across various industries and is known for its reliability, performance,

and scalability.

Allen-Bradley (Rockwell Automation): Allen-Bradley, a brand under Rockwell

Automation is another major player in the PLC market. Their ControlLogix and

CompactLogix PLC families are popular choices for industrial automation

applications, offering advanced features and compatibility with Rockwell’s

integrated architecture.

Schneider Electric: Schneider Electric offers a comprehensive range of PLCs

under their Modicon brand. These PLCs are known for their flexibility, robustness,

and support for various communication protocols, making them suitable for

diverse industrial applications.

Mitsubishi Electric: Mitsubishi Electric is a leading manufacturer of PLCs,

particularly in the Asian market. Their MELSEC series of PLCs is widely used

worldwide and is known for its high performance, reliability, and extensive

networking capabilities.

ABB: ABB provides a range of PLCs under their AC500 series, offering flexible

and scalable solutions for industrial automation. Their PLCs are known for their

reliability, ease of use, and support for various programming languages.

Omron: Omron offers a wide range of PLCs, including the CP1, CJ2, and NJ

series, designed for different industrial automation applications. Their PLCs are

known for their compact design, high-speed processing, and advanced

functionality.

Beckhoff Automation: Beckhoff Automation specializes in PC-based control

systems, including PLCs. Their TwinCAT system offers a unique combination of

PLC, motion control, and HMI capabilities provide powerful and flexible

solutions for industrial automation.

Delta Electronics: Delta Electronics is a global provider of industrial automation

solutions, including PLCs. Their DVP series of PLCs are known for their

reliability, affordability, and ease of use, making them popular choices for small to

medium-sized applications.

These are just a few of the top PLC brands in the market, and there are many other

reputable manufacturers offering high-quality PLCs and related automation products.

When choosing a PLC brand, it’s essential to consider factors such as reliability,

performance, scalability, compatibility with existing systems, and support services

offered by the manufacturer.

Dixon Brass Quick Connect Fittings MC2720806C Industrial Couplers$25.00

Dixon Brass Quick Connect Fittings MC2720806C Industrial Couplers$25.00 Ashcroft 436-11 Pressure Gauge 0–600 PSI Lower Mount 1/4″ NPT Industrial$5,000.00

Ashcroft 436-11 Pressure Gauge 0–600 PSI Lower Mount 1/4″ NPT Industrial$5,000.00 Clark-Reliance Simpliport PW-24 Replacement Module Boiler Gauge System$5,000.00

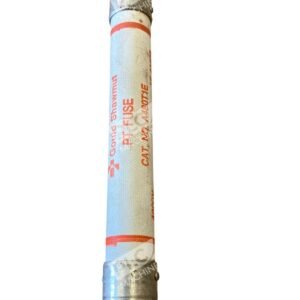

Clark-Reliance Simpliport PW-24 Replacement Module Boiler Gauge System$5,000.00 Gould Shawmut A480T1E PT Fuse Potential Transformer Current Limiting 4.8kV 50kA$159.99

Gould Shawmut A480T1E PT Fuse Potential Transformer Current Limiting 4.8kV 50kA$159.99 RCD Axial Power RCD160F Wirewound Resistor 0.47Ω 0.5% 5W C202$25.00

RCD Axial Power RCD160F Wirewound Resistor 0.47Ω 0.5% 5W C202$25.00 Cornell Dubilier CDE MFP4W1 Metallized Film Capacitor 1µF 400V$25.00

Cornell Dubilier CDE MFP4W1 Metallized Film Capacitor 1µF 400V$25.00 CAPAR 18.4320MHz Quartz Crystal Resonator HC-49/U UART Clock Oscillator$5,000.00

CAPAR 18.4320MHz Quartz Crystal Resonator HC-49/U UART Clock Oscillator$5,000.00 M-Tron SRMP-1 14.31818MHz Crystal Resonator HC-49/U Series Resonant$5,000.00

M-Tron SRMP-1 14.31818MHz Crystal Resonator HC-49/U Series Resonant$5,000.00 International HTD 40M450 Axial Aluminum Electrolytic Capacitor 40µF 450V$5,000.00

International HTD 40M450 Axial Aluminum Electrolytic Capacitor 40µF 450V$5,000.00 RBR56L14701BP Precision Wirewound Resistor Axial Lead MIL-Spec$5,000.00

RBR56L14701BP Precision Wirewound Resistor Axial Lead MIL-Spec$5,000.00 Johanson T3-5 8126 Air Variable Capacitor$5,000.00

Johanson T3-5 8126 Air Variable Capacitor$5,000.00 Fujisoku AS2N 27 DPDT On-On Hyper-Miniature Slide Switch PCB Mount Gold Contacts$5,000.00

Fujisoku AS2N 27 DPDT On-On Hyper-Miniature Slide Switch PCB Mount Gold Contacts$5,000.00 GE 29F730 Axial Aluminum Electrolytic Capacitor Polarized 40µF 30V$5,000.00

GE 29F730 Axial Aluminum Electrolytic Capacitor Polarized 40µF 30V$5,000.00 Siemens 81006 Aluminum Electrolytic Capacitor Axial Lead 10/100$25.00

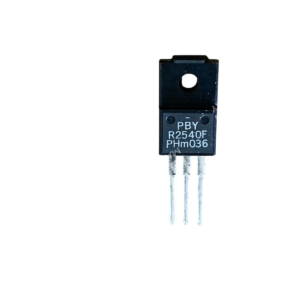

Siemens 81006 Aluminum Electrolytic Capacitor Axial Lead 10/100$25.00 PBY R2540F Power MOSFET Transistor Fully Isolated High Voltage Fast Switching$5,000.00

PBY R2540F Power MOSFET Transistor Fully Isolated High Voltage Fast Switching$5,000.00 Taiyo Yuden UX050 B101K Rutilcon Axial Ceramic Capacitor 100pF Lots of 1000$5,000.00

Taiyo Yuden UX050 B101K Rutilcon Axial Ceramic Capacitor 100pF Lots of 1000$5,000.00 RSF-1 Metal Oxide Film Resistor 750KΩ 1W ±5% Axial – Lots of 100$5,000.00

RSF-1 Metal Oxide Film Resistor 750KΩ 1W ±5% Axial – Lots of 100$5,000.00 Mitsumi MD11-UB3691 RF Modulator TV Tuner Module Coax Output$5,000.00

Mitsumi MD11-UB3691 RF Modulator TV Tuner Module Coax Output$5,000.00 FST Mini Speaker 5269T04 Internal Magnetic Speaker w/ FFC Cable$5,000.00

FST Mini Speaker 5269T04 Internal Magnetic Speaker w/ FFC Cable$5,000.00 Ace 220uF 6.3V Aluminum Electrolytic Radial Lead Power Filter Capacitor$5,000.00

Ace 220uF 6.3V Aluminum Electrolytic Radial Lead Power Filter Capacitor$5,000.00