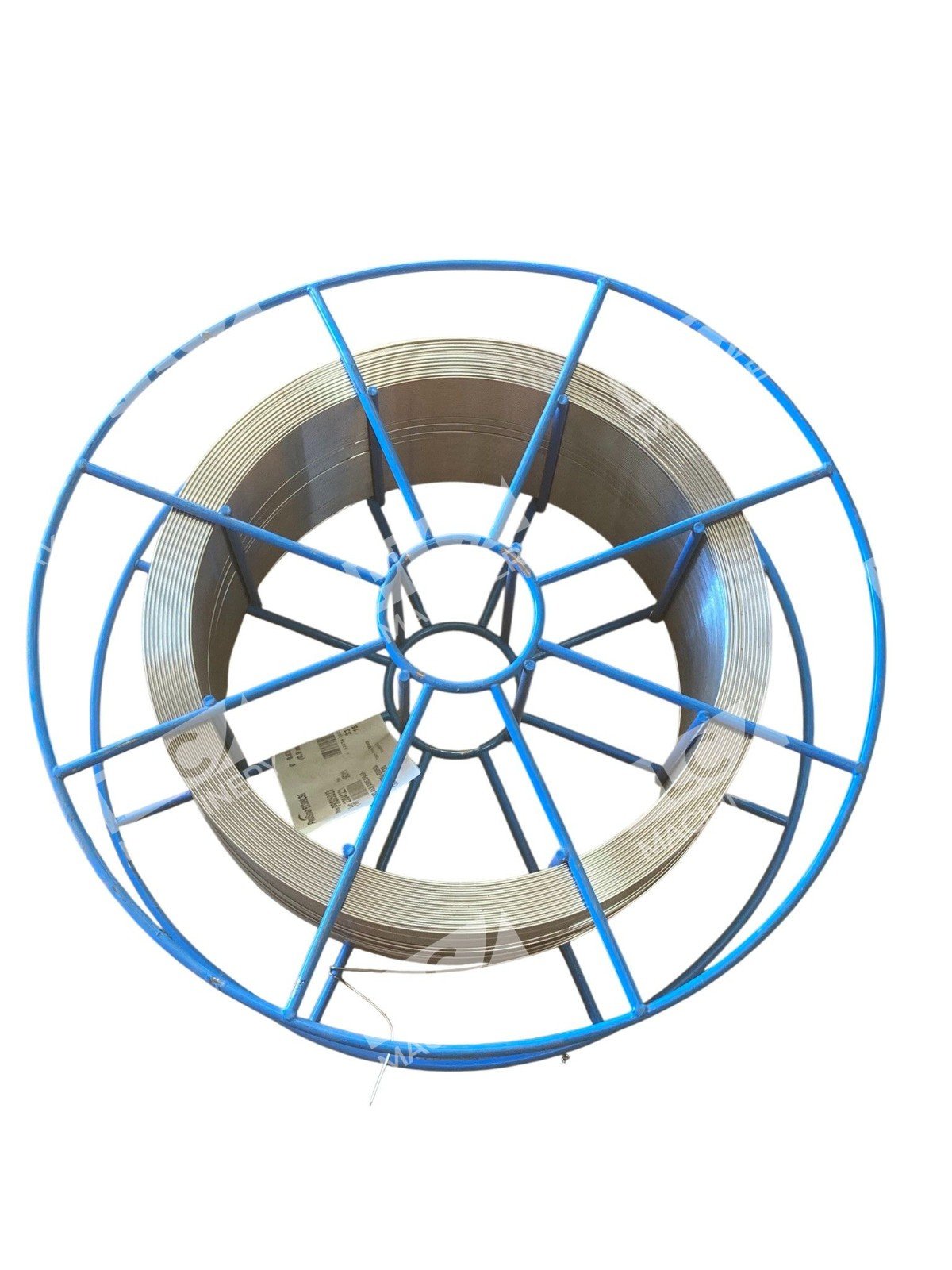

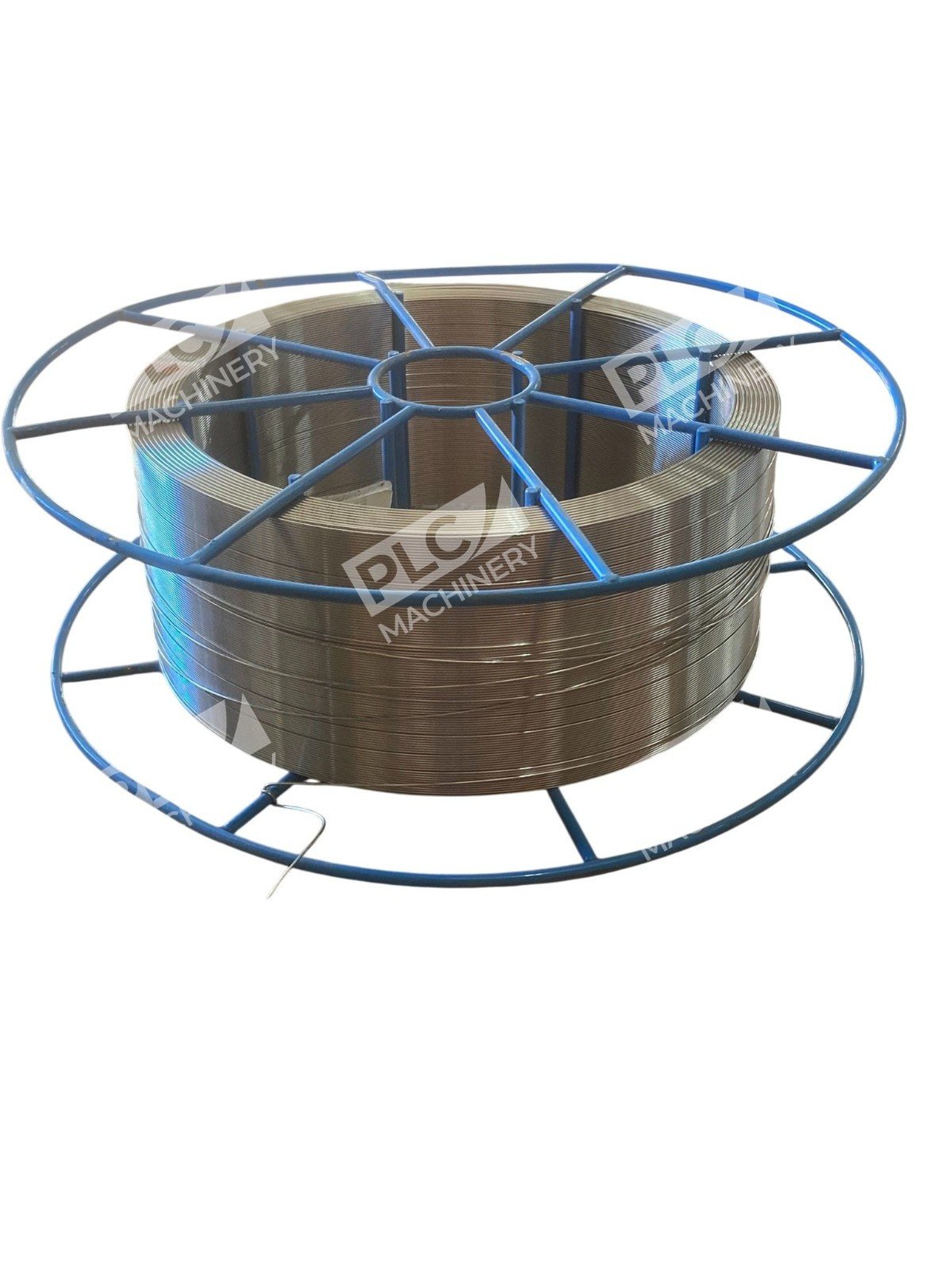

The ProStar ER309LSi Stainless Steel MIG Welding Wire, with a diameter of 0.035 inches and a 33-pound spool (PRS05023), is engineered for superior performance in welding applications involving stainless steel to carbon steel, as well as for overlaying and joining dissimilar metals.

Enhanced Silicon Content for Improved Weld Quality

This welding wire features a higher silicon content compared to standard ER309L wires, resulting in improved arc stability and a smoother bead appearance. The increased silicon enhances the fluidity of the weld pool, ensuring better wetting and reduced spatter during the welding process.

Versatile Applications

The ER309LSi wire is ideal for welding dissimilar metals, such as joining stainless steel to mild or low alloy steel. It is also suitable for use as a buffer layer before hard-facing applications and for stainless steel overlays on mild and carbon steel surfaces.

Mechanical Properties

The deposited weld metal exhibits the following typical mechanical properties:

- Tensile Strength: Approximately 89,000 psi

- Yield Strength: Approximately 60,500 psi

- Elongation: Approximately 35%

Chemical Composition

The typical chemical composition of the ER309LSi welding wire includes:

- Carbon (C): 0.019%

- Chromium (Cr): 23.50%

- Nickel (Ni): 12.95%

- Manganese (Mn): 1.85%

- Silicon (Si): 0.84%

- Phosphorus (P): 0.008%

- Sulfur (S): 0.006%

- Molybdenum (Mo): 0.15%

Conformance to Standards

This welding wire conforms to the following standards:

- AWS A5.9: ER309LSi

- ASME SFA A5.9

Recommended Shielding Gas

For optimal performance, it is recommended to use a shielding gas mixture of 98% Argon and 2% Oxygen.

The ProStar ER309LSi Stainless Steel MIG Welding Wire is a reliable choice for professionals seeking high-quality welds in applications involving stainless steel and dissimilar metal joints.

Reviews

There are no reviews yet.