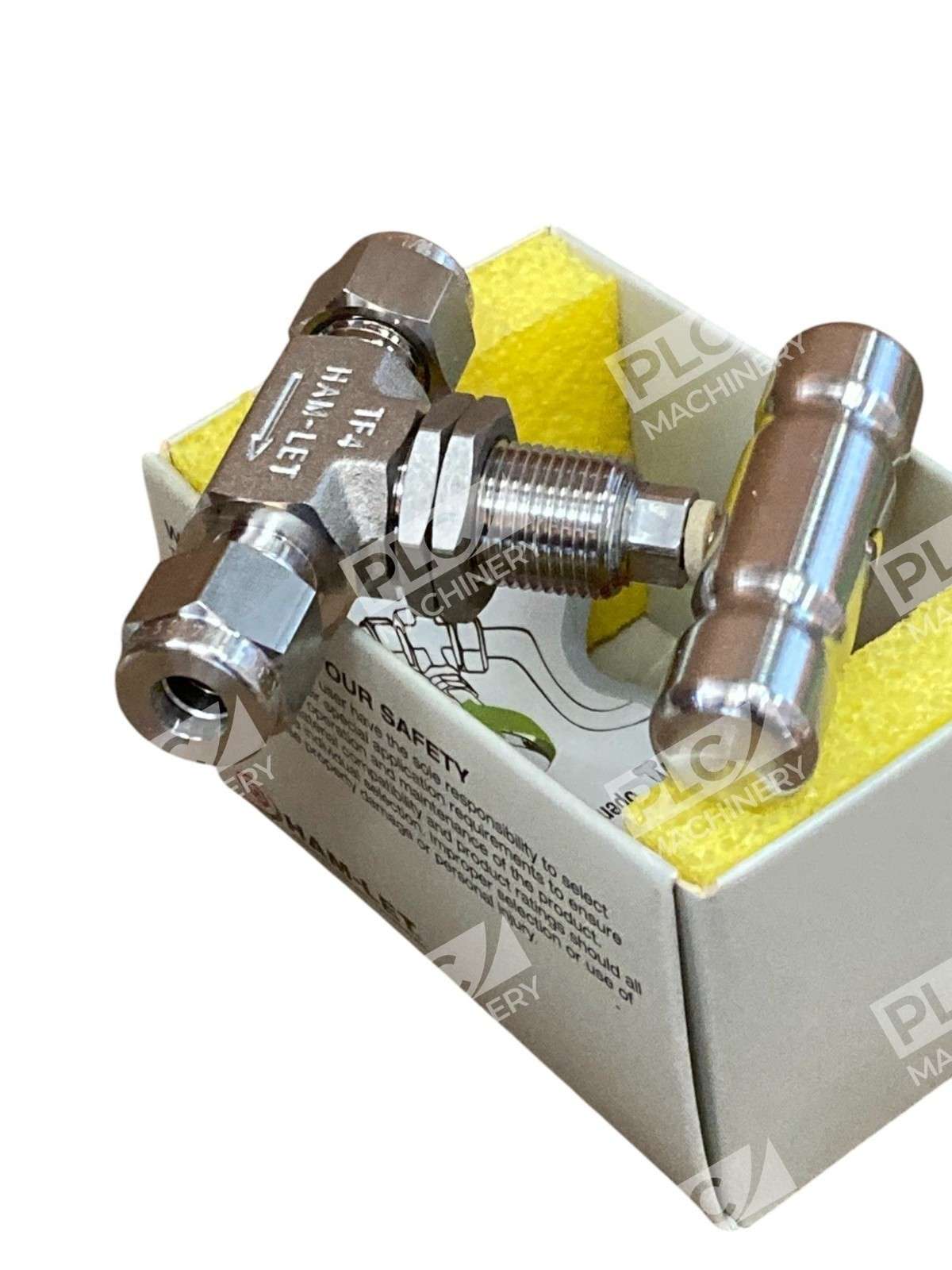

The Ham-Let VLV-45585K86 H-300U Series Stainless Steel Needle Valve is a high-performance component designed for precise flow control in high-pressure instrumentation systems.

Key Features

- High-Pressure Capability: Operates efficiently up to 5,000 psi (345 bar), making it suitable for demanding applications.

- Temperature Range: Handles temperatures up to 446°F (230°C), accommodating various operational environments.

- Compact Design: Its space-saving structure is ideal for instrumentation panels where space is limited.

- Material Construction: Crafted from AISI 316 stainless steel, offering excellent corrosion resistance and durability.

- Stem Options: Available with multiple stem types, including regulating, V-stem, non-rotating, and soft seat, to meet diverse application needs.

- Easy Installation: Features a packing bolt design that allows for straightforward panel mounting without disassembling the packing, ensuring safety and maintaining the manufacturer’s warranty.

- Enhanced Sealing: Utilizes Chevron stem packing for low operational torque and Belleville washers to compensate for packing wear, ensuring a reliable seal over time.

- Surface Treatment: The stem undergoes a special low-temperature carbon diffusion process, enhancing surface hardness and wear resistance while reducing operational torque.

Applications

The H-300U Series Needle Valve is ideal for use in high-pressure instrumentation systems, including power generation, chemical processing, and semiconductor manufacturing. Its robust design and versatile features make it suitable for both shut-off and flow regulation tasks in various industrial settings.

Specifications

- Maximum Operating Pressure: 5,000 psi (345 bar)

- Maximum Operating Temperature: 446°F (230°C)

- Body Material: AISI 316 Stainless Steel

- Stem Material: AISI 316 Stainless Steel

- Connection Types: LET-LOK®, NPT, and ISO threads

- Handle Options: Round plastic, round aluminum, and metal bar handles

The Ham-Let VLV-45585K86 H-300U Series Stainless Steel Needle Valve combines durability, precision, and ease of installation, making it a reliable choice for critical flow control applications.