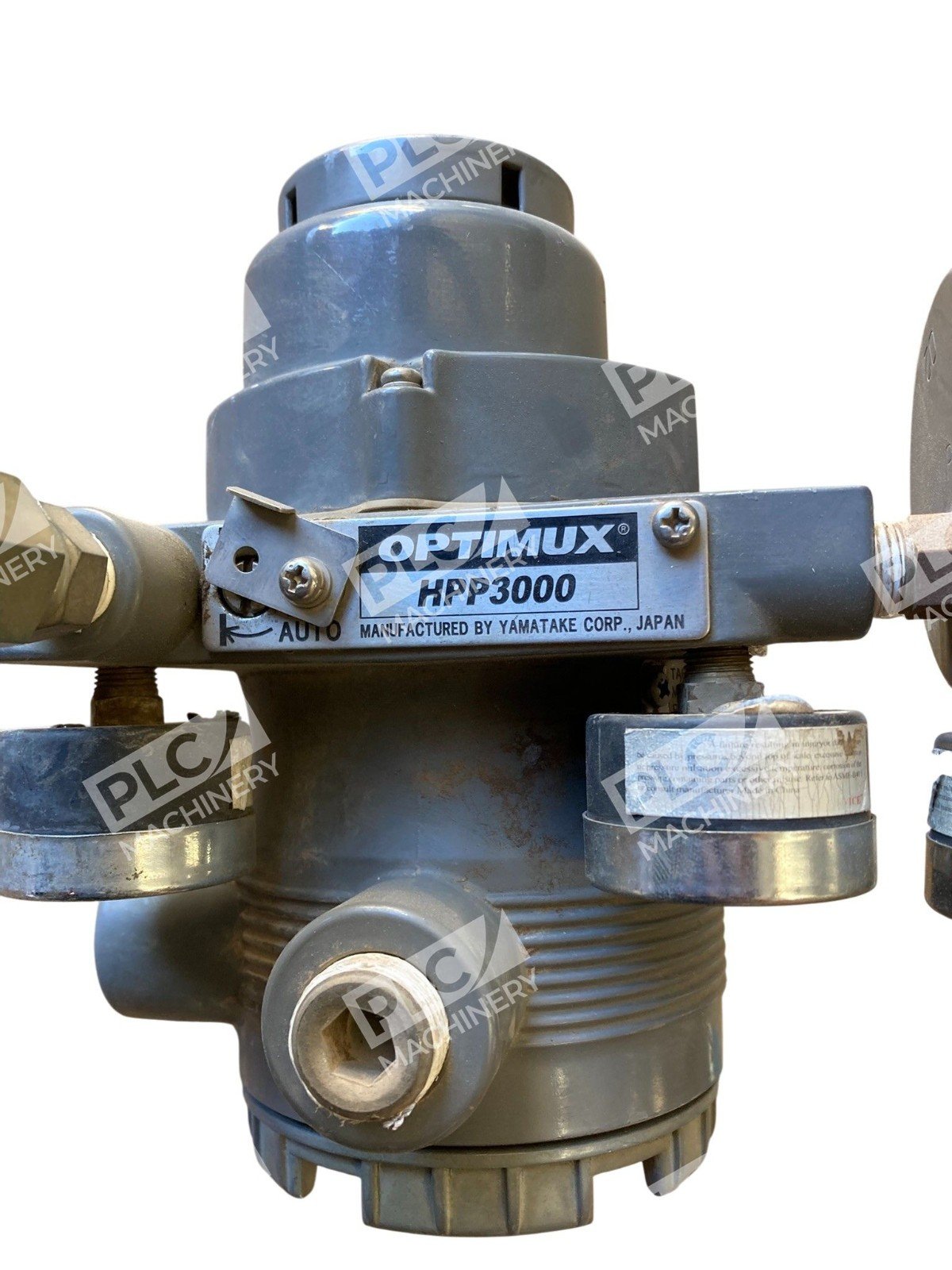

Optimux HPP3000 HART® Smart Valve Positioner AVP3A2-FSD5X

The Optimux HPP3000 HART® Smart Valve Positioner AVP3A2-FSD5X is a high-performance, microprocessor-based current-to-pneumatic positioner designed to enhance the precision and efficiency of valve control systems. This advanced device integrates seamlessly with various communication protocols, including HART®, DE®, and FOUNDATION™ Fieldbus, offering versatile compatibility for diverse industrial applications.

Key Features

- Control Signal Input: Accepts a 4-20 mA DC control signal, which also powers the unit, ensuring streamlined operation.

- Output Characteristics: Provides linear, equal percentage, quick opening, and custom-configurable outputs with up to 15 segments, allowing for tailored control responses.

- Power Requirements: Operates efficiently within a current range of 3.85 mA DC to 24 mA DC, accommodating various system demands.

- Enclosure: Features a robust design equivalent to NEMA 4 and IEC IP66 standards, offering superior protection against environmental factors.

- Approval Bodies: Certified by FM, CENELEC, NEPSI, and CSA for explosion-proof and intrinsically safe applications, ensuring compliance with stringent safety standards.

- Digital Communications: Supports HART®, DE®, and FOUNDATION™ Fieldbus protocols, facilitating flexible integration into existing control systems.

- Air Supply Pressure: Operates effectively with air supply pressures ranging from 20 to 100 psi (130 to 700 kPa), accommodating various pneumatic requirements.

- Vibration Tolerance: Withstands vibrations up to 2G at frequencies between 5 to 400 Hz, ensuring reliable performance in dynamic environments.

- Ambient Temperature Range: Functions optimally in temperatures from -40°F to 175°F (-40°C to 80°C), suitable for extreme operating conditions.

- Relative Humidity: Maintains performance in humidity levels between 10% and 90% RH, adapting to varying environmental moisture.

- Weight: Weighs approximately 5.5 lbs (2.5 kg), facilitating straightforward installation and handling.

- Performance Metrics: Exhibits a hysteresis of 1.0% FS, repeatability of 0.4% FS, and sensitivity of 0.025% of span, ensuring precise control and consistency.

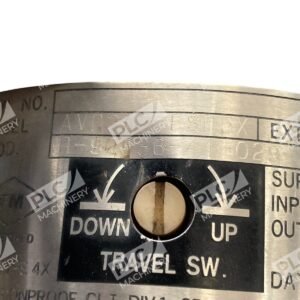

- Stem Travel Range: Accommodates feedback lever angles from ±4° to ±20°, providing flexibility for different valve configurations.

Advanced Functionality

The HPP3000 series is equipped with state-of-the-art features designed to enhance productivity and operational efficiency:

- Automatic Configuration: Simplifies setup processes, reducing commissioning time and potential for human error.

- Split Range Options: Allows for precise control in applications requiring split range operation, enhancing versatility.

- Custom Characterization: Supports up to 16 points of characterization, enabling tailored control responses to meet specific process requirements.

- Self-Diagnostics: Continuously monitors system performance, providing real-time diagnostics to preemptively identify and address potential issues.

These features collectively contribute to increased productivity and efficiency in industrial plant operations, ensuring reliable and precise valve control.

Technical Specifications

- Control Signal Input: 4-20 mA DC

- Output Characteristics: Linear, equal percentage, quick opening, custom configurable (15 segments)

- Power Requirements: 3.85 mA DC to 24 mA DC

- Enclosure: NEMA 4 equivalent, IEC IP66 equivalent

- Approval Bodies: FM, CENELEC, NEPSI, CSA

- Digital Communications: HART®, DE®, FOUNDATION™ Fieldbus

- Air Supply Pressure: 20 to 100 psi (130 to 700 kPa)

- Vibration Tolerance: 2G at 5 to 400 Hz

- Ambient Temperature Range: -40°F to 175°F (-40°C to 80°C)

- Relative Humidity: 10% – 90% RH

- Weight: 5.5 lbs (2.5 kg)

- Hysteresis: 1.0% FS

- Repeatability: 0.4% FS

- Sensitivity: 0.025% of span

- Stem Travel Range: Feedback lever angle ±4° to ±20°

The Optimux HPP3000 HART® Smart Valve Positioner AVP3A2-FSD5X stands as a robust and versatile solution for precise valve control, offering advanced features and broad compatibility to meet the demands of modern industrial applications.

Reviews

There are no reviews yet.