Timken 382A-20024 Tapered Roller Bearing Cup

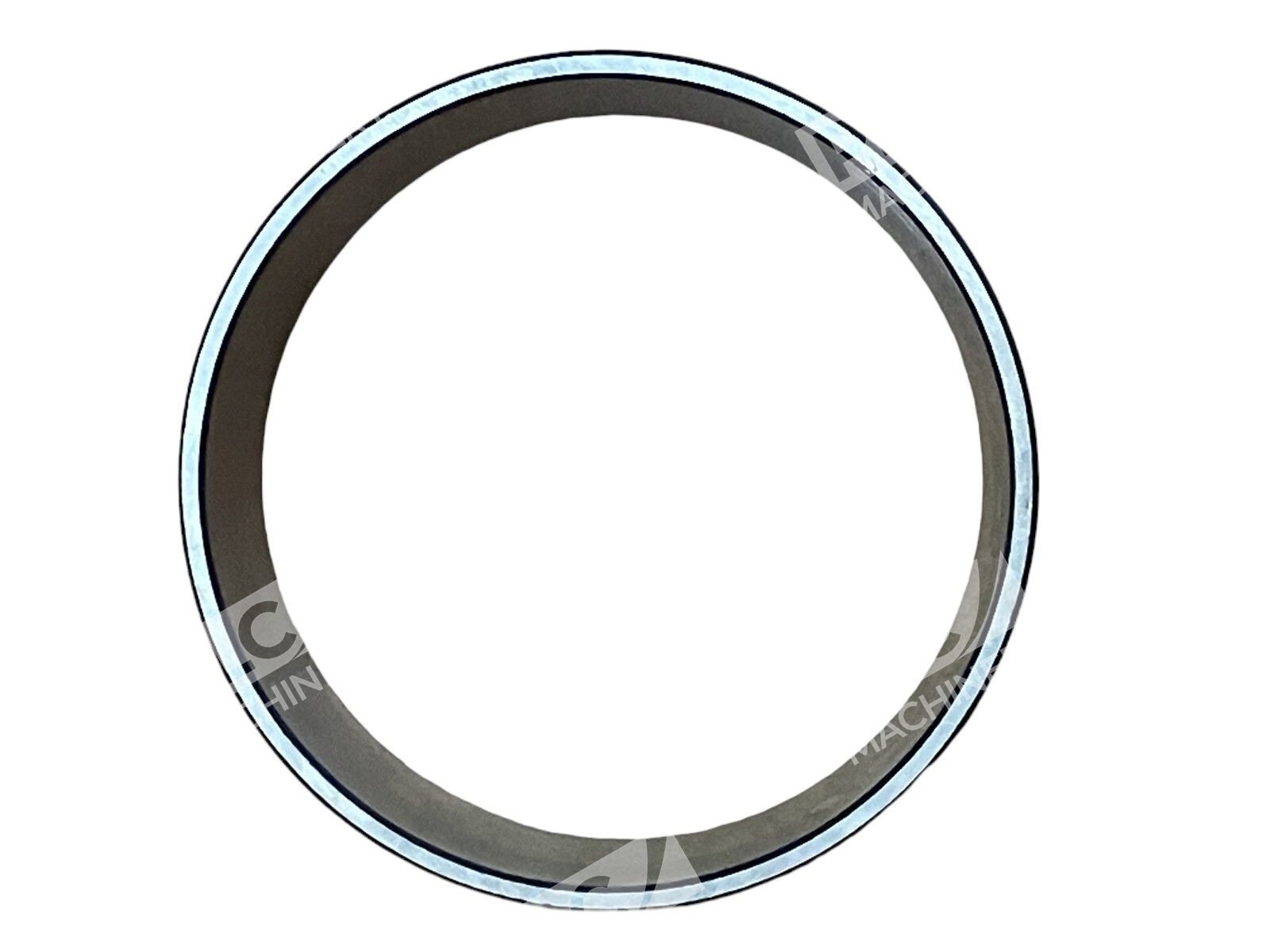

The Timken 382A-20024 is a precision-engineered tapered roller bearing cup, designed to serve as the outer raceway in single-row tapered roller bearing assemblies. This component is integral to managing both radial and axial loads, ensuring optimal performance across various industrial applications.

Key Features

- High Load Capacity: Engineered to handle substantial radial and axial loads, making it suitable for demanding applications.

- Precision Machining: Manufactured with tight tolerances to ensure a perfect fit with corresponding bearing cones, facilitating smooth rotation and minimizing wear.

- Durable Construction: Made from high-grade, heat-treated steel to enhance durability and wear resistance, even in challenging operating conditions.

- Optimized Design: The tapered configuration provides optimal contact with rollers, ensuring even load distribution and reducing friction.

- Interchangeability: Designed for compatibility with matching cones, allowing flexibility in replacements and repairs without the need to replace the entire bearing assembly.

Specifications

- Outer Diameter (D): 3.8125 inches (96.84 mm)

- Cup Width (C): 0.625 inches (15.88 mm)

- Weight: Approximately 0.4 lbs (0.18 kg)

- Series: 385

- Material: Chrome Steel

- Finish: Uncoated

Applications

The Timken 382A-20024 bearing cup is widely utilized in various sectors, including:

- Automotive: Essential in wheel hubs, transmissions, and differentials where high load capacity and durability are critical.

- Industrial Equipment: Used in machinery such as mining equipment, construction vehicles, and industrial gearboxes, requiring reliable performance under heavy loads.

- Agricultural Machinery: Found in tractors, combines, and other farming equipment to ensure smooth operation under high stresses.

- Railway and Marine: Suitable for applications where both radial and axial loads are present, such as rail car axles and marine propeller shafts.

For optimal performance and longevity, it is recommended to replace both the cup and cone components simultaneously, ensuring compatibility and preventing potential issues arising from differing internal profiles or tolerances.

Reviews

There are no reviews yet.